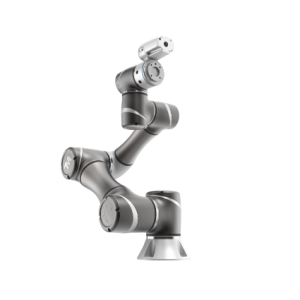

I-6 Axis Automatic Collaborative Robot Arm ye-Welding Cutting Painting kunye nePalletizing

I-6 Axis Automatic Collaborative Robot Arm ye-Welding Cutting Painting kunye nePalletizing

Udidi oluphambili

I-AGV AMR / ijekhi yokuphakamisa i-AGV AMR / i-AGV yemoto ekhokelwayo ezenzekelayo / irobhothi ye-AMR ezimelayo / i-AGV AMR imoto yokuphatha izinto zoshishino / umenzi waseTshayina Irobhothi ye-AGV / indawo yokugcina i-AMR / AMR jack up ephakamisa i-laser SLAM navigation / AGV AMR irobhothi ephathwayo / AGV AMR chassis laser irobhothi yobuchule bokuhamba ngeSLAM

Ukwazisa ngengalo yokuphatha yerobhothi etshintsha umdlalo, ibhegi kunye nebhokisi yokupakisha, isisombululo esiza kuguqula inkqubo yokupakishwa kunye nokuphathwa kweshishini. Le ingalo yerobhothi yokusika yenzelwe ukwandisa ukusebenza kakuhle kunye nemveliso ngelixa uqinisekisa ukuphathwa ngokukhuselekileyo nokukhuselekileyo kweengxowa, iibhokisi kunye neepakethi.

Njengoko imfuno yesantya kunye nokuchaneka iqhubeka ikhula kwimveliso kunye ne-logistics, i-industrial palletizing, ukupakisha, ibhegi kunye necala lokupakisha iingalo zerobhothi zokuphatha iingalo zerobhothi yeyona mpendulo. Zihambile iintsuku zomsebenzi wezandla kunye nomngcipheko wempazamo yomntu. Le ingalo yerobhothi iphuculwe icwangciswe ukuba ibelula, ipakishe kwaye iphathe zonke iintlobo zeengxowa, iibhokisi kunye neepakethi, ibonelela ngemisebenzi engenamthungo kunye nexesha elincinci lokuphumla.

Ingalo yokuphatha yerobhothi yokusetyenziswa kwimizi-mveliso, i-palletizing, ukupakisha, kunye nokupakishwa kweengxowa kunye neebhokisi, ineseti engenakulinganiswa yeempawu eziyibeka ngaphandle kwiindlela zendabuko. Ingalo yerobhothi ixhotyiswe ngeenzwa ze-state-of-the-art kunye neteknoloji yokuqinisekisa ukunyakaza okuchanekileyo kunye nokuhambelanayo, ukuphelisa ukuba kunokwenzeka ukungahambi kakuhle okanye umonakalo kwiimveliso eziphathwayo. Izakhono zayo ezikhawulezayo, ezidityaniswe nokukwazi ukubona ngokuchanekileyo kunye nokulungelelanisa imilo kunye nobukhulu obuhlukeneyo, ukwandisa kakhulu isantya kunye nokusebenza kakuhle kwemisebenzi yokupakisha.

Ukongeza, le ingalo yerobhothi iguquguquka ngendlela emangalisayo, iyenza ilungele amashishini ahlukeneyo. Ukusuka ekusetyenzweni kokutya ukuya kumayeza, kwindawo yokugcina impahla ukuya kwimveliso, esi sisombululo serobhothi sinokuziqhelanisa nomthungo kwiindawo ezahlukeneyo kunye nemisebenzi. Nokuba uphatha iibhegi ezinobunzima obahlukeneyo, ukupakisha iibhokisi ngokuchaneka, okanye ukupakisha iimveliso ngononophelo, i-industrial palletizing, ukupakisha, kunye nebhokisi yokupakisha iingalo zokuphatha irobhothi sisisombululo esigqibeleleyo.

Isishwankathelo, i-Industrial Palletizing Bag Box Packaging Robot Handling Arm ngumdlalo otshintshayo kwishishini lokupakisha kunye nokuphatha ilizwe. Ngeempawu zayo eziphambili, ukusebenza kakuhle okungenakulinganiswa kunye nokuguquguqukayo, esi sisombululo siguquguqukayo siya kuhlengahlengisa ishishini ngokunyusa kakhulu imveliso, ukunciphisa iindleko zabasebenzi kunye nokuqinisekisa ukhuseleko lwemveliso. Hlala uphambi kokhuphiswano kwaye wamkele ikamva lemizi-mveliso ezenzekelayo ngeengalo zethu zerobhothi ezibukhali.

Isicelo

I-AMB Series I-Chassis engabhalwanga i-AMB (i-Auto Mobile Base) ye-agv isithuthi esizimeleyo, i-chassis yendalo yonke eyenzelwe i-agv izithuthi ezilawulwayo ezizimeleyo, ibonelela ngeempawu ezifana nokuhlelwa kweemephu kunye nokuhamba kwendawo. Le chassis ingenamntu yenqwelo ye-agv ibonelela ngobubanzi obuninzi bonxibelelwano olunje nge-I/O kunye ne-CAN ukufaka iimodyuli ezahlukeneyo eziphezulu kunye nesoftware yabathengi enamandla kunye neenkqubo zokuthumela ukunceda abasebenzisi ukuba bagqibe ngokukhawuleza ukwenza kunye nokusetyenziswa kwezithuthi ezizimeleyo ze-agv. Kukho imingxunya emine enyukayo kumphezulu woluhlu lwe-AMB ye-chassis engaqhutywanga kwi-agv yezithuthi ezizimeleyo ezikhokelwayo, ezixhasa ukwandiswa okungafunekiyo nge-jacking, rollers, manipulators, i-latent traction, ukubonisa, njl.njl. ukufezekisa izicelo ezininzi ze-chassis enye. I-AMB kunye ne-SEER Enterprise Enhanced Digitalization inokuqonda ukuthunyelwa ngokudibeneyo kunye nokuthunyelwa kwamakhulu eemveliso ze-AMB ngaxeshanye, nto leyo ephucula kakhulu inqanaba lobukrelekrele lolungiselelo lwangaphakathi kunye nothutho kumzi-mveliso.

Uphawu

·umthamo womthwalo: 150kg & 300kg

·ubuninzi. jacking ukuphakama: 50mm

·ukuchaneka kwendawo yokukhangela: ±5mm

·ukuchaneka kwe-engile yokukhangela: ±0.5°

● Iimpawu ezityebileyo ziyafumaneka nanini na

Iimpawu ezibanzi nezigqwesileyo ezisemgangathweni kunye nezinto ezityebileyo nezisebenzayo eziphambili zinceda abathengi ukuba bafikelele ngokulula kulungiselelo olukrelekrele.

● Amaqonga ezinto ezininzi akhoyo ukuze kwandiswe

Ukubonelela ngamaqonga e-150kg kunye ne-300kg ukuhlangabezana neemfuno zomthwalo kunye neendawo zamashishini ahlukeneyo. Inokusetyenziswa kwakhona kunye ne-manipulators, i-roller, i-jacking, i-latent traction, i-pan / i-tilt, isikrini sokubonisa, njl.njl. ukufezekisa izicelo ezininzi nge-chassis enye.

● ±5 mm, esebenzayo kwaye ichanekile

I-algorithm ye-Laser SLAM isetyenziselwa ukufezekisa ukuchaneka okuphezulu kwendawo, kunye ne-laser non-reflective ephindaphindiweyo yokuchaneka kwendawo ngaphakathi kwe-± 5 mm, eyenza i-docking engenamthungo phakathi kweerobhothi ezihambayo kunye nabantu, kunye nokuhamba ngokufanelekileyo kwemithwalo phakathi kwamanqaku ahlukeneyo. Qaphela: Amaxabiso okwenene axhomekeke kwiimeko zokusingqongileyo

● Ukukhangela okuzinzileyo kukhuseleko nokuthembeka

I-Laser SLAM navigation, i-laser reflector navigation, ikhowudi ye-QR yokuhamba kunye nezinye iindlela zokuhamba zidityaniswe ngokugqibeleleyo kwaye zitshintshwe ngokukhawuleza ukuze kuqinisekiswe umsebenzi ozinzile werobhothi ehambayo.

● Ukuhanjiswa ngokulula kunye nolawulo olubonakalayo

Uluhlu olupheleleyo lwesoftware exhasayo kunye neenkqubo zedijithali zinokuqonda ngokulula ukusebenza, ukucwangciswa kunye nolawulo lolwazi lweerobhothi eziphathwayo, kwaye ziqhagamshele ngaphandle komthungo kunye nenkqubo ye-MES yefektri ukuqonda ngokwenyani i-smart logistics.

Iimveliso ezinxulumeneyo

Ukuchazwa kweParameter

Ishishini lethu